CNC Machining: Precision and Innovation in Modern Manufacturing

CNC Machining: Precision and Innovation in Modern Manufacturing

Blog Article

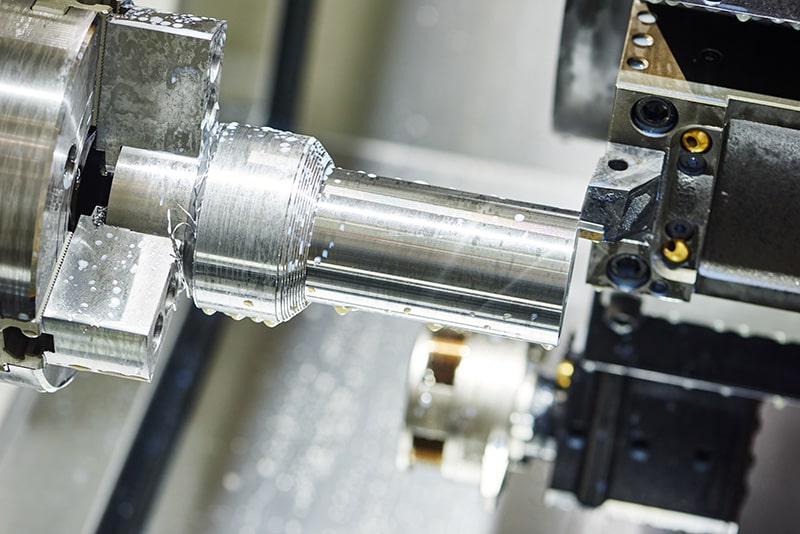

CNC machining has revolutionized manufacturing, offering a reliable and accurate technique for manufacturing parts and components across a wide array of industries. It is a cutting-edge technology that uses computer-controlled machines to carry out cutting or drilling, milling and many other actions on substances like metals, plastics and wood. The degree of precision gained through CNC milling is unrivaled that allows intricate designs to be carried out in a highly precise manner. Through replacing manual input with automation, CNC machines have significantly reduced the possibility that human error will occur and has also improved the speed of production. The combination of precision and efficiency has helped make CNC the machining process a crucial element of manufacturing today.

What lies at the heart of CNC machining is the ability to transform digital drawings into actual parts. Utilizing computer-aided design (CAD) software engineers and designers can create detailed 3D models of the desired part. These digital designs are then transformed into precise directions, known as "G-code," which the CNC machine uses to execute operations like cutting, drilling and milling. Digital control provides the highest level of precision that manual milling cannot attain. It also means that when a plan is integrated into the machine it will repeat in perfect synchronization, resulting in similar parts in large numbers without needing manual adjustments. It is crucial to have this repeatability in industries where precision and consistency are essential.

One of the most significant benefits of CNC Machining is the versatility to work with a vast selection of material. If manufacturers have to deal with tough metals like steel or titanium or softer materials like wood and plastic CNC machines are adjusted to deal with a variety of jobs of shaping and cutting. This makes CNC machine-making suitable for the production of components across a wide range of fields including medical equipment and aerospace parts to automotive and consumer electronics. Being able to process complicated geometries while maintaining high precision has also made CNC machine-making the preferred method to create intricate pieces which would be challenging or even impossible to produce using traditional methods.

CNC machining's versatility is another reason why it is now the foundation of modern manufacturing. The technique can be utilized with a wide range of materials, from hard metals like titanium and stainless steel to softer wood and plastics. This means that CNC machining is suited to make parts suitable for diverse industries including automotive, aerospace, medical, electronics, and consumer goods. In addition, CNC machines can perform various operations including cutting, milling, drilling, engraving, and 3D contouring inside a single set-up. This multifunctionality reduces the need to have multiple machines as well as part transfer, further enhancing efficiency. Whether manufacturing a prototype or assembling large quantities of parts, CNC machining offers the capability to cater for a wide range of needs in production. To receive additional information please go to this website

As well as speed and precision, CNC machining is valued due to its economic efficiency, and especially in large-scale production runs. After the initial set-up and programming of the machine have been completed manufacturing additional components requires minimal input, reducing total production costs. If you are a manufacturer working with costly components like aerospace-grade aluminum, CNC is a method of reducing waste by improving the process of cutting, which ensures that each component produces with little loss of materials. Precision and efficiency are what makes CNC the ideal tool for both prototyping and full-scale production because it allows makers to swiftly test and tweak designs with minimal production cost.

The bottom line is that CNC is now an integral part of modern manufacturing due to its precision as well as its efficiency and flexibility. It has altered the manner parts are produced, allowing to create complex models with high levels of accuracy. It also reduces the cost of production and the time it takes. While it's a large investment at first, the long-term advantages of CNC machining make it a beneficial tool for business across different sectors. As technology evolves, CNC machining is likely to play an even more important role in shaping the future of manufacturing, promoting forward innovation and helping firms adapt to the requirements of a more competitive global marketplace.